Small Hydraulic Breaker Solutions: Maximizing Compact Demolition Efficiency

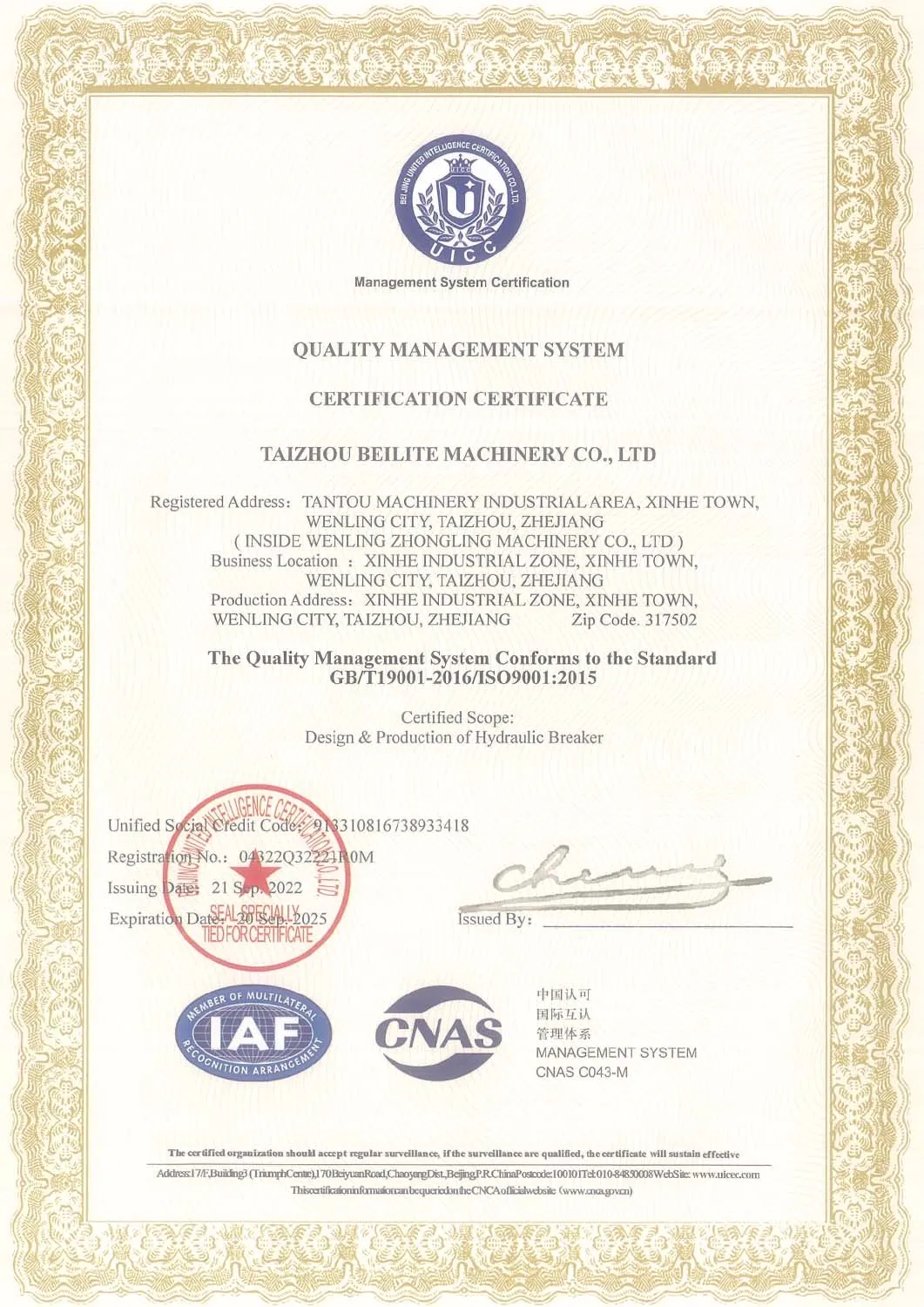

Small hydraulic breakers turn mini excavators and skid steers into serious demolition tools. I've watched these attachments handle jobs that would otherwise require much larger equipment or manual labor, and the difference in project timelines is substantial. When you need precision and power in tight spaces, these compact units deliver both. Beilite Machinery Co., LTD. has built its reputation on high-end hydraulic breakers through continuous innovation and active participation in national standards development. Our focus remains on solving compact demolition challenges with equipment that performs. How Small Hydraulic Breakers Actually Work Small hydraulic breakers convert hydraulic power from the carrier...

English

English French

French